Why FRP is the Smart Choice

A Material That Performs Where Others Fail

| Feature | FRP ✅ | Steel ❌ | Wood ❌ | Aluminum ❌ |

|---|---|---|---|---|

| Corrosion Resistant | ✅ | ❌ | ❌ | ⚠️ |

| Electrical Insulation | ✅ | ❌ | ✅ | ❌ |

| Lightweight | ✅ | ❌ | ✅ | ✅ |

| Custom Moldability | ✅ | ❌ | ❌ | ❌ |

| Low Maintenance | ✅ | ❌ | ❌ | ⚠️ |

| Long-Term ROI | ✅ | ❌ | ❌ | ⚠️ |

5 Critical Reasons to Choose FRP

- Unmatched Corrosion Resistance

FRP won’t rust, rot, or degrade — even in saltwater, wastewater, or chemical environments. That means less downtime, fewer repairs, and longer lifecycle performance. - Lightweight Yet Incredibly Strong

Reduce transportation and installation costs. FRP structures are up to 80% lighter than steel, yet can handle comparable load requirements. - Safety by Design

FRP is electrically non-conductive and available in fire-retardant and anti-slip formats. Ideal for utilities, treatment plants, and public zones where safety matters. - Design Versatility

FRP can be molded into nearly any shape or configuration — manholes, tanks, basins, enclosures, structural supports, and more. - Lower Long-Term Cost

While initial costs may be similar to steel or aluminum, FRP’s low maintenance and longevity drive significant savings over time.

Where FRP Shines

Municipal Infrastructure

Manholes, enclosures, pump basins

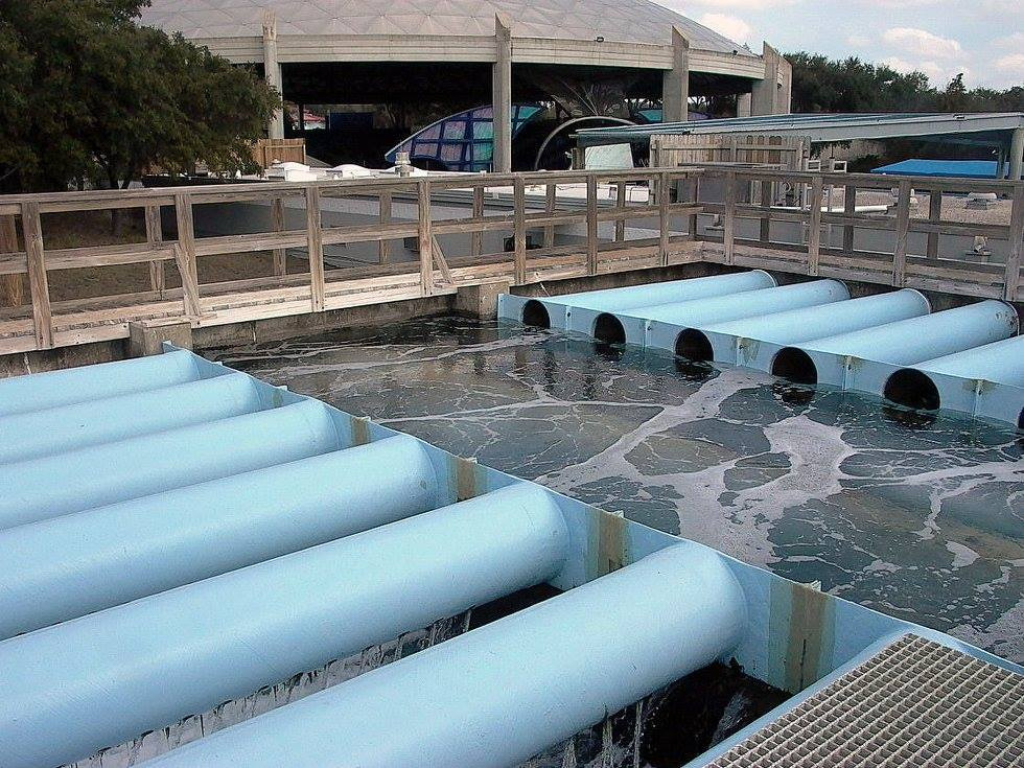

Water & Wastewater Treatment

Launders, skimmers, degas towers

Aquariums & Zoological Projects

Non-corrosive tanks and shelters

Chemical Processing

Resistant vessels, chemical containment

Proven in the Field